On this page we inform you about news and interesting information in the field of filtration and our company. Subscribe here to receive our newsletter and you will be updated automatically.

Merry Christmas and a happy new year

At the end of the pre-Christmas season, many are currently in the last working week of the year.

We wholeheartedly wish you a merry Christmas, a contented reflection on the past, a little faith in the future and hope for the future.

We wish you good luck and good health for the new year and look forward to a trusting cooperation in 2019.

24.12.2018

Bag Filter Housing

Depending on the flow rate, operating pressure, temperature and fineness requirement we offer the right filter bag housing. With a bag filter insert as the filter medium, these housings are used from metal cutting through filtration of water to the food industry.

03.12.2018

Filter Fleece in Cooling Lubricant Filtration

In metalworking, the treatment of cooling lubricants is essential in order to ensure qualitative requirements for the machined part as well as the protection of the system components (pumps, valves, nozzles, etc.). To clean the cooling lubricant, belt filter systems are used which retain machining residues such as metal chips or abrasive particles with the aid of nonwovens. The properties of filter fleece are i.a. determined by the choice of material (PES, PP, viscose, etc.), the type of solidification (chemical, thermal, mechanical) or the grammage. Our filter fleeces are suitable for all machining processes such as drilling, turning, milling, honing, lapping or grinding.

31.10.2018

Magnetic Rods in Filtration

Magnets are used for the filtration of iron-containing particles e.g. in metalworking, surface finishing and the food industry. For that purpose, a magnetic rod is placed before the actual filter, on which the metal particles from the liquid deposit. As a result, the actual filter lasts longer, which means that it has to be changed less frequently and costs can be saved. The magnetic rod itself can be cleaned and reused. With a magnetic flux density of around one tesla, our magnetic rods are among the strongest permanent magnets, making them almost ten times stronger than standard horseshoe magnets.

04.04.2018

Meltblown and String Wound Filter Cartridges

Filter cartridges are commonly used in meltblown or wound versions.

The first string wound filter cartridge came on the market in the beginning of the 20th century. The basic structure is still unchanged: Depending on requirements, a polypropylene, cotton or fiberglass yarn is wound onto a core (PP, PVDF, stainless steel) to be selected. The yarn is wound more loosely toward the outside in order to achieve a stepwise filtration of coarse to fine particles.

An alternative to this are the somewhat "younger" meltblown filter cartridges manufactured by the meltblown process. Here, the polymer is melted in an extruder and pressed through several nozzles. The exiting fibers are transferred to the rotating cartridge via a stream of air. Again the density of the fiber layers can be varied, e.g. through the rotational speed. At constant fiber density, it is also possible to filter absolutely with meltblown filter cartridges.

Would you like to know more about our filter cartridges? Contact us for a personal conversation!

12.03.2018

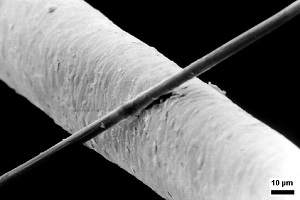

Fibers for Felt Production

Felts are among the oldest textiles and are still made of animal hair such as sheep wool. Animal fibers have the property to hook themselves together due to their scale structure and thereby to matt. The synthetic polymer fibers used in our filters don't have this property. Here, the solidification is usually done by mechanical methods such as needle punching or water jetting, in which the fibers are intertwined with each other by stinging needles or by a focused jet of water. These processes can be used for all types of fibers and are today's standard for technical nonwovens in the filtration sector.

19.02.2018