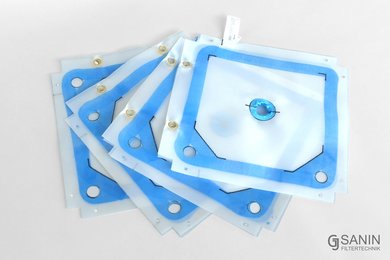

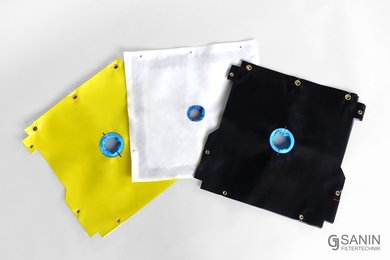

Filter cloths are used in numerous applications where solids have to be filtered from liquids. Every filter cloth is individually manufactured for you. With various fabric qualities, we optimize parameters like the cake release property, the cleaning or the wear behaviour together with you. Depending on your process, we will support you with our knowledge whether for the purification of fluids or the extraction of solids depending on your target.

| Designs: | Single filter cloths, barrel-neck cloths or overhang cloths with single and double layering |

| Materials: | Polypropylene, polyamide, polyester, polyacrylonitrile, polyphenylene sulphide (PPS), polyvinylidene fluoride (PVDF), polytetrafluoroethylene (PTFE) |

| Sizes: | 250 to 2000 mm |

| Air permeability: | 2 to 1500 l/dm²/min |

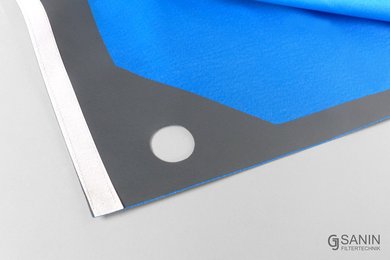

| Accessories: | Brass, stainless steel or nickel-plated eyelets as well as non-metallic mounting lugs; cloth necks from different materials (rubber neck,…); edge coating (rubber coating); cam reinforcement; Velcro; drip-tight versions with EPDM cords; sewed on supporting/drainage cloths; thermal surface treatments like e.g. calendering |

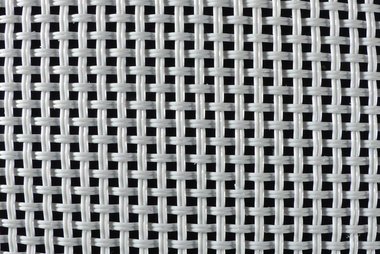

Monofil Filter Cloths

Threats used for the production of these qualities consist of continuous filaments or plastic wires respectively.

Properties: very little blockages, very high dry content, good cake release properties, long lifetime, easy to clean, best regenerative ability after washing

Filter Cloth Qualities Multifil

Multifil means, that the threats used during weaving consist of at least two continuous filaments. The number of fibers remains constant over the length of the threat.

Properties: increased abrasion resistance, high strength, retention of fine particles, high deposition rate

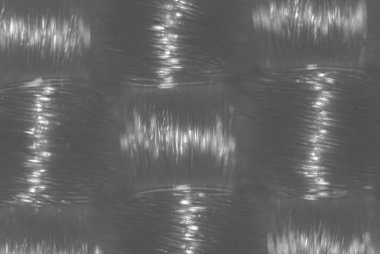

Staple Fiber Filter Cloths

Spinning threads, which are further processed to staple fibers and therefore restricted in length are the foundation of these filter cloths. After twisting them to a yarn they can be used in the weaving process.

Properties: excellent retention of fine particles, very good initial filtration with little or no clouded filtrate but a clear filtrate

Monofil/multifil Filter Cloths or the like

Moreover different combinations of threats are possible during weaving. For instance, filter cloths made from fabrics which consist of monofil warp threads and multifil weft threads are often used.

Properties: A combination of the various portrayed ones

Drainage Filter Cloths

The flow resistance of the filter cloth itself as well as of the filter cloth base is crucial. The flow rate of the filtrate is reduced where the medium lays on the supporting bars or knobs. Because of the lower effective filter surface, the filter cloth resistance increases. This problem can be dealt with by inserting drainage cloths between filter cloth and filter press element.

Properties: Reduction of flow resistance, lifetime extension, better cake drying, better cake release properties

FAQS:

In the following you will find the most frequently asked questions concerning the filtration with filter cloths and filter fabrics:

| 1. | My filter cloths wear too quickly. How can I increase the service life of my filter cloths? |

| 2. | I would like to filter with higher fineness. Which fabric quality can you recommend me for my application? |

| 3. | The filter cloths of my manufacturer are very expensive. Can you offer the same quality at a lower price? |

| 4. | How can I reduce downtimes caused by contaminated/dirty filter cloths? |

| 5. | How to optimally clean my filter cloths? What possibilities for the cleansing of the different filter fabrics exist? |

| 6. | What is the right filter cloth for my process? |

| 7. | There is no filter cake formation. Can I prevent this by changing the filter fabric? |

| 8. | The filter cake is too wet. What can I do about it? |

| 9. | My disposal and/or water costs are too high. How can I reduce them? |

| 10. | My current filter cloths clog/block too soon. How can this problem be solved? |

| 11. | How can I reduce the flow/filtration resistance? |

| 12. | Which filter fabric is suited for my fruit press? |

No matter whether you found your concern here or if you have further questions, don't hesitate to contact us!

![[Translate to Englisch:] Filtertuchgewebe aus Stapelfasern [Translate to Englisch:] Filtertuchgewebe aus Stapelfasern](/fileadmin/_processed_/8/6/csm_Filtertuchgewebe_aus_Stapelfasern_21ebcf86b7.jpg)